Main Products

Our main products include U-shape screw conveyor, pipe screw conveyor, WLS shaftless screw conveyor, tilted screw conveyor, vertical screw conveyor, DSZ single axis dust humidifier, SJ Biaxial dust humidifier and other equipments.

Reverse pulse bag filter dust collector

LCM-D/G series long bag off-line pulse dust remover is a large-scale dust

Industrial cyclone dust collector

The XLP type cyclone dust collector is a high-efficiency cyclone dust collector.

Cyclone industrial dust collector

It is used to remove dense non-fibrous andcohesive dust from industrial exhaust gases.

High - Pressure Fog Cannon: Efficient Dust Suppression and Air Purification for Construction Sites

Model: JY-20 JY-30 JY-40 JY-50 JY-60 JY-80 JY-100 JY-120

Industrial reverse pulse baghouse filter dust collector

Fiber bag type components are used to filter and collect solid particulates in dust gas.

Food grade stainless steel tubular screw conveyor

Tubular screw conveyors and feeders have a wide range of applications in powder and granular material handling.

High - Efficiency Slurry Screw Conveyor: Optimal for Mud Transportation in Industrial Applications

Slurry screw conveyor is widely used in Petroleum project, for handling the slurry from well drilling.

The LSF series sand water separator is used in the sand-collecting tank of the sewage treatment plant.

Hot Selling Products

The main equipments include: environmental protection series and conveying equipment series. We can use computer-aided drafting according to the customer's on-site requirements, and provide an effective design scheme to meet the customer's usage requirements.

The explosion-proof and dust-free polishing worktable is completely unique in human design.

LCM-D/G series long bag off-line pulse dust remover is a large-scale dust

High - Quality Screw Blades & Auger Flights: Unbeatable Cost - Performance for Diverse Applications

Classify: With shaft, Non shaft, Continuous, Piece type

The LSF series sand water separator is used in the sand-collecting tank of the sewage treatment plant.

CORPORATE STRENGTH

Your Reliable OEM Partner

Botou Ever Lucky Environmental Protection Machinery Co. , Ltd. (abbreviation: Ever Lucky Machinery) is an professional manufacturer of environmental machinery with more than 20 years of experience in research, design, manufacturing, sales, installation, commissioning and after-sales service. The main equipments include: environmental protection series and conveying equipment series. The two major series constitute the production team of 120 production lines with 10 production teams in the 4 main workshops of Ever Lucky Machinery.

Founded in

Main workshops

Production lines

Production teams

OUR ADVANTAGE

"One-time choice, whole life service and long-term friendship”We are constantly striving and innovating to win a very high appraisal from our customers with our first-class products and first-class after-sales service. Let us create a better future together.

Manufacturer Strength

Ever Lucky Machinery is an professional manufacturer of environmental machinery with more than 20 years of experience

Equipment Quality

Environmental protection series and conveying equipment series constitute 120 production lines in 4 workshops of Ever Lucky Machinery

Production Team

We have professional R&D talents and technical specialists, with rich material resources and human resources with 10 production teams.

OEM & ODM

We can use computer-aided drafting according to the customer's on-site requirements, and provide an effective design scheme to meet the customer's usage requirements.

Our Customers

We have many cooperative customers at home and abroad, welcome to visit

Leave Your Contact Info

We Will Provide You With Service

For inquiries about our products, please email to us and we will be in touch within 24 hours.

Monday to Friday 08:00-18:00

E-mail: sales01@everluckymachinery.com

We Support Customization

Continue To Create Greater Value For Customers

Blog & Events

We can customize production according to customer requirements and implement comprehensive quality management in all aspects of production and sales.

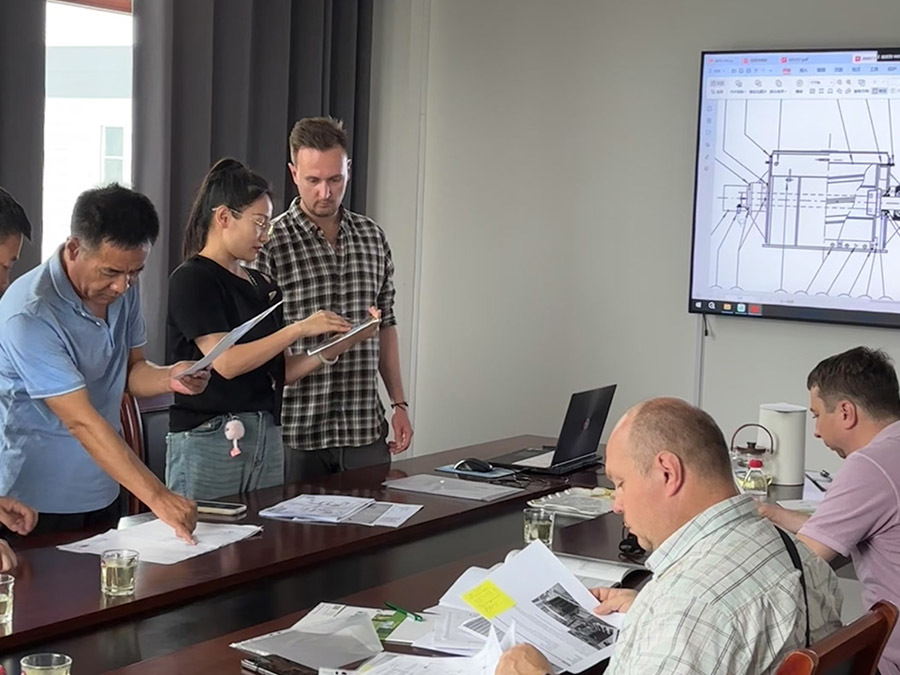

Russian Customers come to visit our factory We have professional R&D talents and technical specialists, with rich material resources and human resources, and use computer-aided drafting according to the customer's on-site requirements, and provide an effective design scheme to meet the customer's usage requirements.

Analysis of the Causes of Damage to the Blade of Screw Conveyor

The main wear parts of screw conveyor are screw blade, hanging bearing and screw end.

Analysis of common waste gas treatment methods

Air pollution is one of the most prominent environmental problems in the world. The main source of pollutants is industrial waste gas.

Common Faults, Causes and Solutions of Bag Filter

Under the current pressure of environmental protection, many industries are facing a severe test, and enterprises are also putting environmental protection in an important position of development.