PRODUCTS

CONTACT INFO

Email: sales01@everluckymachinery.com

Whatsapp: +86-13722852356

Wechat: ff0082006

Sype: 297338284@qq.com

Tel: +86-317-5660915

Fax: +86-317-8330026

Address: Botou city Hebei province

High - Performance Sand - Water Separation Screw Conveyor: Ideal for Efficient Solid - Liquid Separation in Industrial Applications

The LSF series sand water separator is used in the sand-collecting tank of the sewage treatment plant.

Category

Contact Info

sales01@everluckymachinery.com

Product Details

The LSF series sand water separator is used in the sand-collecting tank of the sewage treatment plant. The sand-water mixed liquor discharged from the sand-collecting tank is used for sand-water separation.

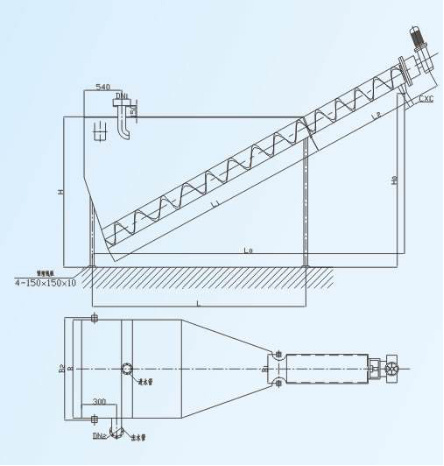

The spiral sand water separator is installed with an inclination of 20°-30°. sand-water mixed material enters the water tank from the inlet pipe, and the particles with larger specific gravity (such as sand grains) in the mixed liquid are deposited on the bottom of the spiral groove due to the drop of self-weight surface. Under the urging of the screw, the material is lifted along the bottom of the inclined U-shaped groove, and after leaving the liquid surface, it continues to move a certain distance. The water in the sand gradually flows back into the water tank in the gap in the spiral groove. The sand also gradually dries at the discharge port and falls on other conveying devices depending on its own weight. The supernatant is continuously drained from the drain to achieve sand separation.

Equipment Features:

1) The separation efficiency can reach 96% -98%, and particles with diameter ≥ 0.2mm can be separated out;

2) Adopt shaftless screw, waterless bearings, easy maintenance;

3) Compact structure and light weight;

4) The new type of transmission device, it is key component - reducer is advanced shaft-mounted, no coupling, easy installation;

5) The lining strips are quick-fitting and easy to replace;

6) The spiral axial position can be adjusted to facilitate the adjustment of the safety clearance between the end and the wall.

Model number | SLF260 | SLF320 | SLF355 | SLF420 |

Flow rate(m3/h) | 15-55 | 55-80 | 80-110 | 110-130 |

Tank capacity (m3) | 1.25 | 1.8 | 3.2 | 4.3 |

Power(kw) | 0.25 | 0.37 | 0.75 | |

Dehydration rate(%) | >96 | |||

L(mm) | 3850 | 4390 | 5850 | 6280 |

B(mm) | 1260 | 1500 | 1600 | 1750 |

H1(mm) | 1500 | 1500 | 2150 | 2150 |

H(mm) | 1520 | 1730 | 2400 | 2550 |

Keywords

Leave Us A Message

*Note: Please fill in the information accurately and keep the communication open. We will contact you as soon as possible.