PRODUCTS

CONTACT INFO

Email: sales01@everluckymachinery.com

Whatsapp: +86-13722852356

Wechat: ff0082006

Sype: 297338284@qq.com

Tel: +86-317-5660915

Fax: +86-317-8330026

Address: Botou city Hebei province

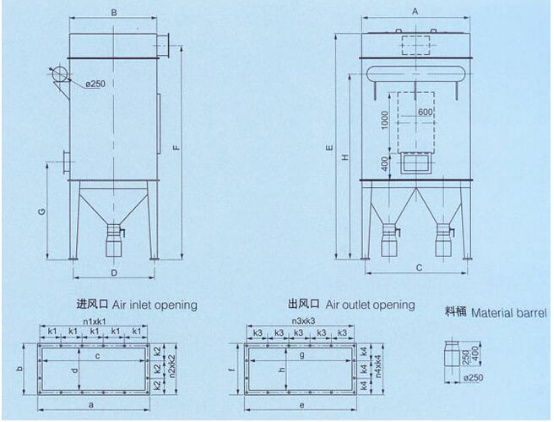

Industrial reverse pulse baghouse filter dust collector

Category

Contact Info

sales01@everluckymachinery.com

Product Details

Fiber bag type components are used to filter and collect solid particulates in dust gas, and such filter is widely used in the industries in terms of power station, metallurgy, cement, glass, chemicals and papermaking etc.

Fiber bag type components are used to filter and collect solid particulates in dust gas, and such filter is widely used in the industries in terms of power station, metallurgy, cement, glass, chemicals and papermaking etc.

Model number | MC24 | MC36 | MC48 | MC60 | MC72 | MC84 | MC96 | MC120 | |

Filter area (m2) | 18 | 27 | 36 | 45 | 54 | 63 | 72 | 90 | |

| Bag quantity (pc) | 24 | 36 | 48 | 60 | 72 | 84 | 96 | 120 | |

Pulse valve (pc) | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 20 | |

Air volume | 2160—4300 | 3250—6480 | 4320—8630 | 5400—10800 | 6450—12900 | 7550—15100 | 8650—17300 | 10800—20800 | |

Dimension | 1025×1678 | 1425×1678 | 1823×1678 | 2225×1678 | 2625×1678 | 3075×1678 | 3949×1678 | 4389—1678 | |

| Pulse control instrument | JMK—2 type pulse control instrument | ||||||||

| Filter bag size (D×L) | ¢125×2050 | ||||||||

Efficiency (%) | 99—99.5 | ||||||||

Resistance mmH2O | 120—150 | ||||||||

Air speed | 2—4 | ||||||||

Dust content | 3—15 | ||||||||

Air pressure | 4 | ||||||||

Draught Fan model | 4—72—11—4.5A | 4—72—11—5A | 4—72—11—6C | 4—72—11—5A | 4—72—11—6C | ||||

4—72—11—6C | 4—72—11—8C | ||||||||

Compressed air consumption | 0.08—0.34 | 0.13—0.5 | 0.17—0.67 | 0.21—0.84 | 0.25—1.01 | 0.3—1.18 | 0.34—1.34 | 0.42—1.68 | |

Weight (kg) | 830 | 1106 | 1224.30 | 1341.44 | 1564.32 | 2012.35 | 2130.22 | 2410 | |

Keywords

Leave Us A Message

*Note: Please fill in the information accurately and keep the communication open. We will contact you as soon as possible.