PRODUCTS

CONTACT INFO

Email: sales01@everluckymachinery.com

Whatsapp: +86-13722852356

Wechat: ff0082006

Sype: 297338284@qq.com

Tel: +86-317-5660915

Fax: +86-317-8330026

Address: Botou city Hebei province

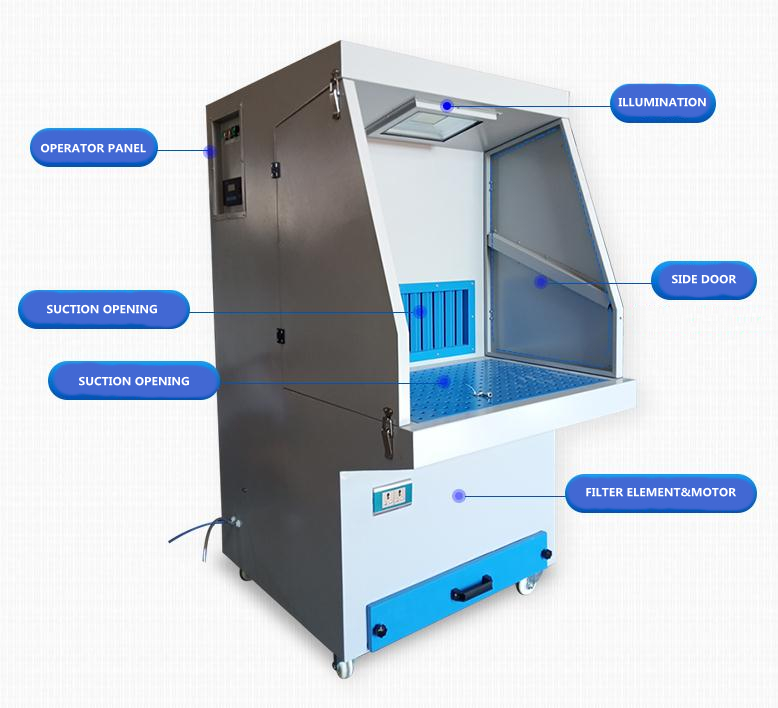

Downdraft table

The explosion-proof and dust-free polishing worktable is completely unique in human design.

Category

Contact Info

sales01@everluckymachinery.com

Product Details

Welding Fume Extractor: Superior Solutions for Clean Welding Environments

Introduction

Diverse Model Range

- Flexibility and Mobility: Ideal for small - scale welding workshops or on - site welding jobs, our portable welding fume extractors are highly maneuverable. They are compact in size, allowing for easy transportation around the workspace. These models are equipped with wheels and a lightweight design, enabling welders to quickly move the extractor to the source of the fumes.

- Application: They are perfect for tasks where the welding location is frequently changing, such as in construction projects or small - batch manufacturing. The portable models can effectively capture and filter welding fumes, protecting the welder's health even in non - stationary work environments.

- High - Volume Extraction: For larger welding workshops with continuous and high - volume welding operations, our stationary welding fume extractors are the go - to choice. These models are designed to handle a large amount of fumes generated over extended periods. They are typically installed permanently in the workshop, often connected to a central ventilation system.

- Performance: With a higher extraction capacity, they can maintain a clean and healthy working environment even in the busiest welding facilities. Stationary models are also more powerful in terms of filtration efficiency, ensuring that a large percentage of harmful welding fumes are removed from the air.

- Work - Surface Integration: Our downdraft tables combine the functionality of a welding workbench with efficient fume extraction. The work surface is designed to allow welding fumes to be drawn downwards through a perforated top. This design ensures that fumes are captured right at the source, minimizing their spread in the workshop.

- User - Friendly: Downdraft tables are popular among welders who need a dedicated work area with built - in extraction. They are easy to use, as the welder can focus on the welding task without having to worry about separate fume - capturing equipment.

Material Options

- Corrosion Resistance and Durability: Welding environments can be harsh, with exposure to moisture, welding spatter, and chemicals. Stainless steel - constructed welding fume extractors offer excellent corrosion resistance, making them suitable for long - term use in such conditions. The material is also highly durable, able to withstand the rigors of continuous operation.

- Hygiene and Ease of Cleaning: In addition, stainless steel has a smooth surface that is easy to clean, which is important for maintaining the efficiency of the extractor. It prevents the accumulation of dust and debris, ensuring that the filtration system works optimally.

- Cost - Effectiveness and Strength: Carbon steel is a cost - effective option that provides good strength for the construction of welding fume extractors. To enhance its performance in welding environments, we apply high - quality protective coatings. These coatings can prevent corrosion and extend the lifespan of the extractor.

- Versatility: Carbon steel with protective coatings is a popular choice for workshops on a budget that still require a reliable and robust fume extraction solution. The coatings can be customized to meet different environmental requirements, such as resistance to specific chemicals or abrasion.

- Lightweight and High - Performance: Some of our models incorporate composite materials. These materials offer a combination of lightweight design and high - performance characteristics. Composite materials can be engineered to have excellent mechanical properties, such as high strength - to - weight ratio, which is beneficial for portable models.

- Innovation and Efficiency: They also contribute to the overall efficiency of the extractor by reducing the weight without sacrificing the structural integrity or the performance of the filtration system.

Filtration Systems

- HEPA Filters

- High - Efficiency Particle Removal: Our welding fume extractors often feature HEPA (High - Efficiency Particulate Air) filters. These filters are capable of capturing at least 99.97% of particles as small as 0.3 microns. This high - level filtration is crucial for removing harmful welding fumes, which can contain fine particles that are dangerous to inhale.

- Health Protection: By using HEPA filters, we ensure that the air expelled from the extractor is clean and safe, protecting the health of welders and other workers in the vicinity.

- Activated Carbon Filters

- Gas and Odor Removal: In addition to particle filtration, some of our models are equipped with activated carbon filters. These filters are effective in removing harmful gases and unpleasant odors generated during welding processes. They work by adsorbing the gaseous pollutants onto their porous surfaces.

- Comprehensive Purification: The combination of HEPA and activated carbon filters provides a comprehensive air - purification solution, ensuring that both particulate and gaseous contaminants are removed from the welding fumes.

| |

| |

Keywords

Leave Us A Message

*Note: Please fill in the information accurately and keep the communication open. We will contact you as soon as possible.