Common Faults, Causes and Solutions of Bag Filter

Jun 20,2019

Under the current pressure of environmental protection, many industries are facing a severe test, and enterprises are also putting environmental protection in an important position of development. Bag filter is an efficient dust removal equipment for air pollution control, which is widely used. Understand the common faults and solutions of bag filter, and can easily deal with emergencies.

Bag filter

1) Working Principle

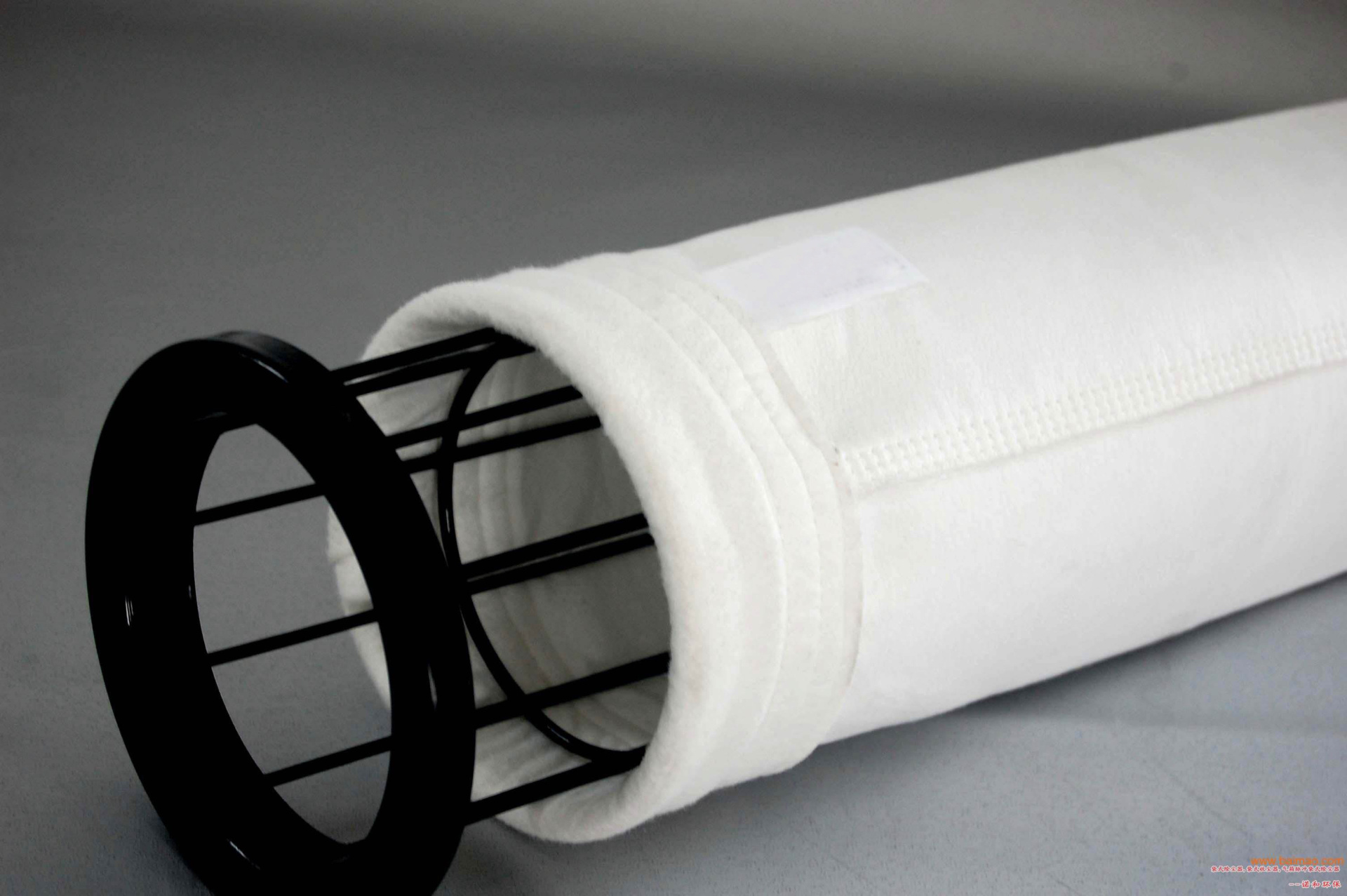

The working principle of the dust collector is to treat the dust in the flue gas through its own cloth bag. This treatment belongs to a mechanical interception, and in the process of intercepting the dust, clean air is discharged from the other end. The intercepted dust collected to a certain extent will be blown into the funnel, and eventually be discharged by the relevant system.

2) Influencing factors of working life

There are two main factors influencing the working life of bag filter:

(1) Dust cleaning frequency.

In the bag filter, in order to prolong the working life of the bag, usually a layer of filter bed should be arranged on the top of the bag. If the cleaning frequency of dust is too high, the bag will be damaged, so the service life of the bag filter will be affected. Therefore, in the process of using, the frequency of dust removal must be set well.

(2) Bag management.

When storing and placing cloth bags, it is necessary to prevent moisture and moisture, direct sunlight and deterioration of cloth bags. At the same time, in the process of installation, fire prevention must be clearly ordered, and the temperature of smoke exhaust should be controlled within a certain range, so as to ensure that the bag filter can work normally.

Common Problems and Solution Strategies of Bag Filter

There will always be some small problems in the installation and work of bag filter, which will seriously affect the efficiency of bag filter and cause certain economic losses to enterprises. Therefore, it is very important to ensure the quality of equipment installation and avoid some unnecessary problems.

1) Installation of bearings

Bearing is the foundation of bag filter. Usually, the installation of bearing of dust collector requires welding treatment of "the lower part of the foundation column and the embedded plate of the foot". But in engineering construction, it will lead to the error of the embedded board, so the vertical degree of the column must be adjusted during installation, otherwise the size of the dust collector frame will not be guaranteed.

Generally, the Stiffeners under the column are welded when they leave the factory. Therefore, in the process of installation, if you encounter such problems, it will be very difficult to solve. So how to solve this problem, we can cut the welded column and stiffener when leaving the factory, so that after adjusting the vertical degree of the column, we can weld the two together and finally weld the embedded plate. In the installation process, through tape measure, level meter, center line detection and other means to check and locate, the final must ensure that the welding process is qualified.

2) Production and installation of ash hoppers

The existence of dust hopper is an important part of the dust collector. The dust collected by the dust collector will be concentrated in the dust hopper, and then processed. Therefore, the installation of ash hopper is more important, but in the production process of ash hopper, in order to save the transportation space and cost, ash hopper components are manufactured and installed in the construction site.

Therefore, due to the constraints of the construction site environment and space, the installation of ash hopper will be difficult. At the same time, the larger space needed in the transportation process will increase the cost of transportation. Most importantly, in the transportation process, the plate is prone to deformation, so the installation difficulty will increase.

In view of this situation, the ash hopper can be divided into two sections during production. At the same time, in order to ensure the installation strength and the quality of the ash hopper, the joint around the ash hopper can be staggered. To a large extent, the difficulty of ash hopper installation is reduced and the quality of ash hopper is guaranteed.

3) Ensure the internal cleanliness of bag filter

A lot of welding will be used in the installation of bag filter. At the same time, there are many temporary bearing in the shell. Therefore, after the installation is completed, the rotary valve under the ash hopper should be removed, because the inside of the dust collector should be cleaned, and after that the rotary valve can be installed after the cleaning. Otherwise, the blockage of the rotary valve will easily occur in the process of using, which will affect the normal use of the bag filter.

4) Installation of housing

The housing is mainly composed of bottom ring beam, column, top beam and side wall plate. In the process of installing the housing, it will be limited by the site. The bottom ring beam is lifted to the position of the support by hoisting, and then assembled into a whole. Because of the relatively large volume of the housing, it is difficult to move to a predetermined position after installation on the ground.

The installation of the shell sheet is an important part of the installation of the bag filter, which requires high air tightness. For this reason, punching can be used in the installation, so that the deformation of the flooring can be prevented. At the same time, the inspection of the air tightness can be carried out through the principle of water tightness. This installation method can solve some minor problems in installation and ensure the installation quality.

5) Installation of Pulse Valve

In the process of installing pulse valve, leakage always occurs. The main reasons are as follows: Firstly, there is a gap between pulse valve and air bag, which leads to leakage. Secondly, there is a problem with the structure of the air chamber. The existence of this problem will lead to the spiral hole connecting the internal and external, and eventually lead to air leakage.

In order to solve these problems, it is necessary to adjust the diameter of the gasket under the pulse valve according to the adjustment of the air bag during the installation of the pulse valve. The bolt can be replaced directly. Through adjustment, the installation quality of pulse valve and bag filter can be guaranteed.

Common Faults and Removal Methods of Bag Filter

1. High pressure difference of dust collector

Main causes and elimination methods:

1) Misreading of differential pressure: Clean up the pressure measuring interface/check whether there are cracks in the trachea/check the differential pressure meter.

2) Incorrect setting of injection system: increasing injection frequency/low pressure of compressed air; increasing pressure/checking dryer, cleaning (if necessary)/checking whether there is blockage in pipeline.

3) Injection valve failure: check diaphragm valve/check control solenoid valve.

4) Impulse Controller Failure: Check whether the controller indicates the contacts/checks the output of each terminal.

5) Clogging of filter bag: coagulation on filter bag (see below); sending filter bag to laboratory for analysis. The filter bags are dried and cleaned to form protective layer and porous and loose primary cake by changing/reducing air flow/increasing compressed air pressure/frequency of cleansing/spraying neutral powder.

6) Excess secondary dusting: continuous emptying hopper/filter bag/filter cartridge cleaning according to random sequence, not sequential cleaning. Check the inlet baffle to make sure it is clean.

2. Fan motor with low current/low air volume

Main causes and elimination methods:

1) High pressure difference of dust collector: see above.

2) Fans and motor pulleys are connected in reverse: check the drawings and connect the pulleys in reverse.

3) Pipeline ash blockage: Clean the pipeline and check the gas flow rate.

4) Blower baffle closure: open baffle and lock in position.

5) Close the lifting valve of the dust collector: check the air passage and open the valve plate.

6) The system static pressure is too high: measure the static pressure at both ends of the fan and check the design specifications, adjust as needed. For high flow rate inspection pipeline replacement, the original bad design.

7) Fan does not operate within the design requirements: check the fan inlet structure to ensure smooth air flow. Check for blade wear and tear, repair or replace as needed.

8) Reverse rotation of fan: connecting the upper wiring of reverse motor.

3. Dust escapes from dust collection point

Main causes and elimination methods:

1) Small air volume: see above.

2) Pipeline leakage: repair cracks so that dust will not bypass the dust collection point.

3) incorrect pipeline balance: adjust the branch pipeline air valve.

4) The design of suction hood is unreasonable: close the open area around the dust collection point; check whether the horizontal suction ventilation device overcomes suction; check whether the dust is taken out of the suction hood by belt.

4. Ash Emission from Chimneys

Main causes and elimination methods:

1) Leakage of filter bags: Replace if the filter bags are torn or have holes; check the installation of spring coils to ensure tightness.

2) Shell sheet leakage: filling or welding seam.

3) No enough dust cake: reduce the pressure of compressed air; reduce the cleaning frequency / spray neutral powder to produce primary dust cake.

4) too many air holes in the filter bag or cartridge: the filter bag or cartridge should be tested for penetration and consulted with the manufacturer.

5. Serious wear and tear of fan

Main causes and elimination methods:

1) Fan handling excessive dust: see above.

2) fan inappropriate: to determine whether the fan is suitable for working conditions; consult the manufacturer.

3) Fan speed is too high: consult manufacturer.

6. Vibration of fan is serious

Main causes and elimination methods:

1) Wheel and leaf ash: Wheel and leaf ash removal, check whether the fan handles excessive dust. Check fan installation position/drain condensate or moisture/keep fan dry.

2) Fan impeller is not suitable for working condition: consult manufacturer.

3) Uneven pulley: the pulley acts as dynamic balance.

4) Bearing wear: replacement.

7. Excessive use of compressed air

Main causes and elimination methods:

1) Over-frequency of cleaning cycle: delaying cleaning cycle (if possible).

2) Injection time is too long: reduce the duration (except after the initial impact, all other gas is wasted; usually the injection is set to 0.1 seconds).

3) Excessive pressure: check diaphragm and spring (see analysis of valve failure).

4) Tracheal leakage: air bubble test and repair.

8. Low Compressed Air Pressure

Main causes and elimination methods:

1) Excessive consumption of compressed air: see above.

2) Inside air pipe resistance: Check whether the trachea is blocked or not.

3) Blockage of dryer: change dryer or bypass dryer if working condition permits.

4) Compressor wear: consult the manufacturer or check the compressor maintenance manual.

9. Excessive air volume

Main causes and elimination methods:

1) Pipeline leakage: filling cracks.

2) Insufficient static pressure: Close the air valve. Reduce fan speed.

10. Low consumption of compressed air

Main causes and elimination methods:

1) Pulse valve does not work: check the pulse valve according to the above method.

2) Controller failure: check terminal output according to the method mentioned above.

11. Premature failure-decomposition of filter bags

Main causes and elimination methods:

1) The filter material is not suitable for this condition: Analyse the chemical properties of the gas and consult the filter bag or filter cartridge manufacturer.

2) The filter material is not suitable for the gas composition: to treat the gas before entering the dust collector; or to replace the filter bag or filter cartridge.

3) Running at acid dew point temperature: raising gas temperature.

12. High failure rate of filter bags - excessive wear and tear

Main causes and elimination methods:

1) wear out of current-sharing baffle: replace current-sharing baffle.

2) Excessive dust: install primary dust collector.

3) Over-frequency of cleaning cycle: prolonging cycle time.

4) Inlet air flow is not properly equalized by filter bag or filter cartridge: consult manufacturer.

5) Dust in the air purifying chamber/ceiling: cleaning the inside of the ceiling and filter bag or filter cartridge; fluorescence test to find the leakage point.

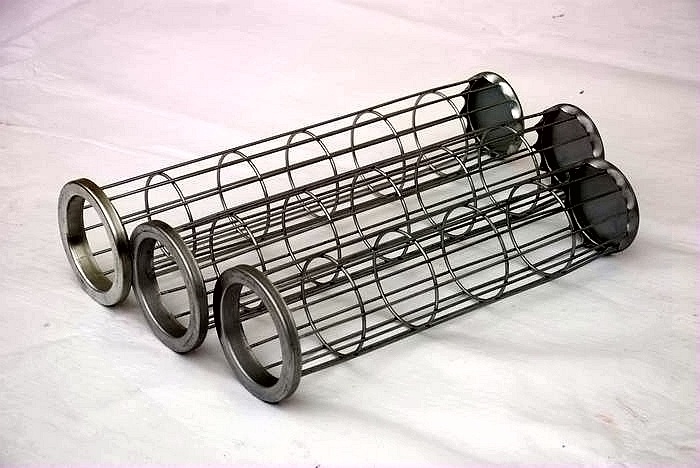

6) There are burrs/corrosion on cage (if used): remove smooth burrs; replace if necessary. If corrosion occurs, consider using a cage with an anticorrosive coating.

13. High failure rate of filter bag - combustion

Main causes and elimination methods:

1) Layered distribution of hot and cold gases: using baffles to solve turbulence in pipes.

2) Spark enters the dust collector: install spark eliminator.

3) Thermocouple failure: replace and find out the cause of failure.

4) Cooling device failure: check the design specifications and consult the manufacturer.

14. Moisture in the dust collector

Main causes and elimination methods:

1) Insufficient heating: before starting to process the air flow, the hot air is input into the system.

2) There is no blowing system after shutdown: the system runs the fan for 15-20 minutes after shutdown.

3) Shell temperature is lower than dew point temperature: increase gas temperature/unit insulation insulation/reduce moisture in the system to reduce dew point temperature.

4) The outside air enters the dust collector: Check whether the shell is leaking and the door seal is worn.

5) Insulation layer through cooler objects: eliminate the direct use of metal as lining.

6) Water vapor in compressed air: check the automatic drain/install secondary cooler or dryer.

7) Worse process conditions: spraying modulating powder.

15. Material bridge in ash hopper

Main causes and elimination methods:

1) Moisture in the dust collector: See above.

2) The design of ash hopper hinders material movement: installing sound horn or vibrator to promote material movement.

3) Dust accumulation in the ash hopper: continuous ash removal; do not store ash in the ash hopper.

4) Conveyor openings are too small: wide-enlarged groove blades are used; feeder/star unloading valve is ineffective or insufficient in size.

Routine checkpoint of bag filter

Air duct: check for corrosion, leaks or any external damage; check for bolt loosening, welding cracks and ash deposits in any part (mainly flat pipe, diameter change).

Electromagnetic/Pulse Valve: See if it works correctly and listen to the sound of compressed air injection.

Pressure Relief Valve: Leakage or not. Pay attention to the debris inside the pressure relief valve.

Fan: Make sure that the fan is installed firmly and horizontally, refueling regularly. Attention should be paid to dust accumulation on blades.

Compressed air system: check whether the compressor is properly lubricated; check whether there are cracks in the air bag and pipeline; pay attention to the pressure indication of the pressure regulating valve (if installed); check whether the air compressor and the air bag are drained.

Overhaul doors: All overhaul doors should be firmly sealed; check whether the sealing strip is loose, broken or worn. Replacement as needed.

Import/guide plate: check for excessive wear or corrosion.

Air flow control valve and lifting valve: check whether the injector (if necessary) is running properly.

Above are some fault phenomena which are easy to occur in the operation of bag filter. Daily maintenance, timely detection and solution of hidden troubles, and stable operation of dust collectors can effectively improve the efficiency of dust removal. The storm of environmental protection is rising again. Has your company done a good job of environmental protection response?

Previous:

Next:

Related dynamics

Contact Us

Email: sales01@everluckymachinery.com

Whatsapp: +86-13722852356

Wechat: ff0082006

Sype: 297338284@qq.com

Tel: +86-317-5660915

Fax: +86-317-8330026

Address: Botou city Hebei province