PRODUCTS

CONTACT INFO

Email: sales01@everluckymachinery.com

Whatsapp: +86-13722852356

Wechat: ff0082006

Sype: 297338284@qq.com

Tel: +86-317-5660915

Fax: +86-317-8330026

Address: Botou city Hebei province

Advanced Cyclone Dust Collector: High - Performance Dust Filtration

BXF-2 high efficiency cyclone separator is a high efficiency separator developed by Nanjing forestry university,

Category

Contact Info

sales01@everluckymachinery.com

Product Details

Advanced Cyclone Dust Collector: High - Performance Dust Filtration

Introduction

Updated Naming and Industry Relevance

Diverse Model Range

Compact - Sized Cyclone Dust Collectors

- Ideal for Small - Scale Operations: These models are tailor - made for small workshops, like those in the jewelry - making, small - batch electronics assembly, or local print - finishing industries. Their compact design allows for easy integration into limited workspaces. Despite their size, they are highly effective at separating dust particles from the air stream, providing a clean working environment even in tight quarters.

- Customizable for Specific Needs: They come with adjustable features such as inlet and outlet configurations, enabling customization based on the particular dust characteristics and air - flow requirements of the small - scale operation. This ensures optimal dust - collection efficiency, regardless of the specific application.

Medium - Capacity Cyclone Dust Collectors

- Versatile for Mid - Sized Industries: Suited for mid - sized manufacturing facilities such as furniture production plants, medium - scale chemical processing units, and light - engineering factories. These collectors can handle a substantial volume of dust - laden air. Their robust build quality ensures they can operate continuously under normal industrial conditions without significant wear and tear.

- Enhanced Separation Efficiency Features: Equipped with advanced cyclone design elements like optimized conical sections and precise air - flow channels, these medium - capacity models offer enhanced dust - separation efficiency. They can effectively remove a broad spectrum of particle sizes, from relatively large debris to finer dust particles, ensuring high - quality air output.

Large - Scale Industrial Cyclone Dust Collectors

- Heavy - Duty Dust Management: Engineered for large - scale industrial operations such as steel mills, cement manufacturing plants, and power generation stations. These large - scale collectors are designed to process massive volumes of air with high dust concentrations. They feature a large - diameter cyclone body and high - strength components to withstand the extreme conditions associated with large - scale industrial dust collection.

- Multi - Stage and Hybrid Options: Some of our large - scale cyclone dust collectors are available in multi - stage configurations or as hybrids, combined with other filtration technologies. Multi - stage setups allow for a more thorough dust - separation process, capturing different particle sizes at each stage. Hybrid models, on the other hand, combine cyclone technology with other methods like bag - filtering or electrostatic precipitation for even higher - efficiency dust removal.

Material Options

Carbon Steel

- Strength and Cost - Effectiveness: Carbon steel is a staple material for our cyclone dust collectors. It provides excellent structural strength, enabling the collectors to endure the high - velocity airflows and the resulting centrifugal forces during operation. This makes it suitable for a wide range of general - purpose industrial applications. Moreover, carbon steel is cost - effective, offering an affordable solution for businesses looking to manage their dust - collection needs without over - stretching their budgets.

- Protective Coating Options: To enhance its durability and resistance to corrosion, especially in harsh industrial environments, we offer a variety of protective coatings for carbon - steel collectors. Epoxy coatings can be applied to protect against moisture and chemical corrosion, while abrasion - resistant coatings are available for applications where the collector is exposed to abrasive dust particles, such as in mining - related operations.

Stainless Steel

- Corrosion Resistance and Hygiene: In industries where corrosion resistance and hygiene are of utmost importance, such as the food, pharmaceutical, and high - purity chemical industries, stainless - steel - constructed cyclone dust collectors are the top choice. Stainless steel offers outstanding resistance to a wide range of chemicals and moisture, preventing rust formation and ensuring a clean and sterile dust - collection environment.

- High - Temperature Tolerance: Certain grades of stainless steel used in our collectors can also withstand high temperatures. This makes them suitable for applications where the dust - laden air is hot, such as in drying processes, incinerators, or some high - temperature manufacturing operations.

Special Alloys

- Tailored for Extreme Conditions: For industries facing extreme operating conditions, such as high - abrasion, high - temperature, or highly corrosive environments, we offer cyclone dust collectors made from special alloys. These alloys are engineered to provide superior performance under these challenging circumstances. For example, in mining and quarrying operations where dust is highly abrasive, wear - resistant alloys can significantly extend the collector's lifespan.

- Performance - Driven Design: Special alloys are selected based on their specific mechanical and chemical properties, ensuring that the cyclone dust collector can perform optimally in the most demanding industrial settings. This may involve alloys with high - strength - to - weight ratios, excellent heat resistance, or enhanced corrosion resistance.

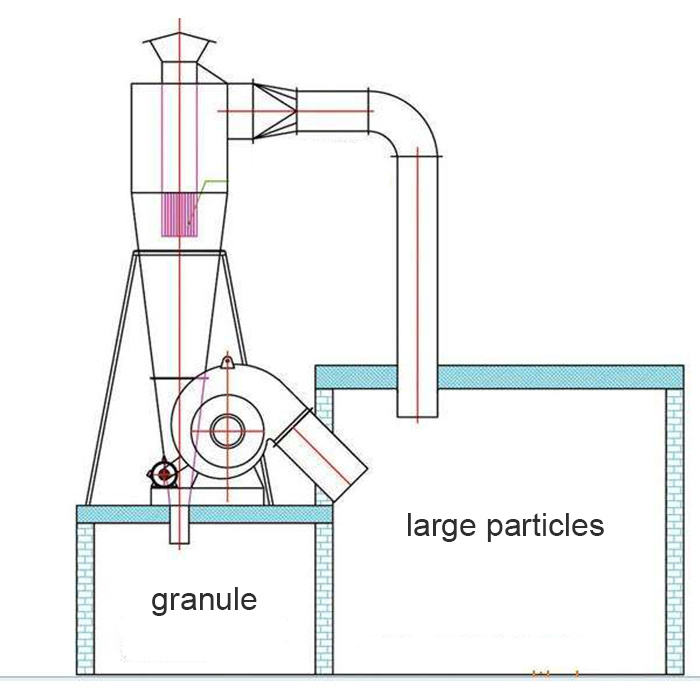

Working Principle and Key Features

Centrifugal Separation Technology

- Efficient Dust Particle Removal: Our Advanced Cyclone Dust Collectors operate on the principle of centrifugal separation. When the dust - laden air enters the cyclone, it is forced into a swirling motion. The centrifugal force generated during this rotation causes the heavier dust particles to be flung towards the outer walls of the cyclone. These particles then slide down the walls and are collected in a hopper at the bottom, while the clean air exits from the top of the cyclone.

- Particle - Size - Based Separation Efficiency: The efficiency of the cyclone in separating dust particles is directly related to their size. Larger particles are more easily separated due to their greater mass and inertia, while smaller particles require a more precisely designed cyclone geometry and air - flow dynamics for effective removal. Our collectors are designed to optimize this separation process for a wide range of particle sizes.

Low - Maintenance and User - Friendly Design

- Simple and Reliable Structure: The cyclone dust collectors are designed with a relatively simple structure, minimizing the number of moving parts. This simplicity not only enhances the collector's reliability but also reduces maintenance requirements. There are no complex filters or membranes that need frequent replacement, as in some other dust - collection systems.

- Accessible Maintenance Points: The design includes easily accessible hoppers and inspection ports. This allows for straightforward cleaning and inspection of the internal components, ensuring that the cyclone can be maintained in peak working condition with minimal effort and downtime.

| Cyclone Separator No | Throughput (m3/h) | Dimensions | ||||

| D | H | Hi | Hz | Entrance Area | ||

| φ-250 | 500 | 250 | 1150 | 425 | 600 | 130x65 |

| φ-300 | 700 | 300 | 1380 | 25 | 700 | 165x75 |

| φ-375 | 1000 | 375 | 1720 | 635 | 900 | 185x95 |

| φ-450 | 1500 | 450 | 2035 | 756 | 1050 | 225x115 |

| φ-550 | 2200 | 550 | 2505 | 935 | 1300 | 270x190 |

| φ-675 | 3200 | 675 | 3055 | 1130 | 1600 | 325x170 |

| φ-800 | 4500 | 800 | 3650 | 1360 | 1900 | 400x200 |

| φ-950 | 6600 | 950 | 4335 | 1625 | 2250 | 490x235 |

| φ-1150 | 9500 | 1150 | 5255 | 1950 | 2750 | 570x290 |

| φ-1400 | 14000 | 1400 | 6395 | 2370 | 3350 | 700x350 |

| φ-1500 | 16000 | 1500 | 6865 | 2540 | 3600 | 750x370 |

Keywords

Leave Us A Message

*Note: Please fill in the information accurately and keep the communication open. We will contact you as soon as possible.