PRODUCTS

CONTACT INFO

Email: sales01@everluckymachinery.com

Whatsapp: +86-13722852356

Wechat: ff0082006

Sype: 297338284@qq.com

Tel: +86-317-5660915

Fax: +86-317-8330026

Address: Botou city Hebei province

impeller feeder discharge valve

The un-loader is the main equipment for the dedusting equipment ash discharge, air supply and other equipment feeding, suitable for powdery materials and granular materials. Category: un-loader

Mainly

Category

Contact Info

sales01@everluckymachinery.com

Product Details

The un-loader is the main equipment for the dedusting equipment ash discharge, air supply and other equipment feeding, suitable for powdery materials and granular materials. Category: un-loader

Mainly divided into A-type unloader, B-type unloader.

Working principle:

The unloader is divided into three types: normal type, pressure type, and high temperature type. The unloader can be driven at a constant speed, continuously discharging material at a controlled rate, or With variable speed drive, the unloader is used as a feeder.

Unloader general type: It can be used on the normal materials below 150 degrees and normal temperature, and can continuously and uniformly feed material into the feeding pipe, and in the system and separation

The dust collection department can also serve as a unloader.

Unloader pressure type: it uses a closed rotor, can be widely used in the suction type, pressure feed air conveying system and negative pressure conveying equipment, rotary discharge

The device can ensure that the pressure of the air flow inside the delivery pipe does not leak, and it can safely transport and collect the materials. Therefore, in this respect, it is called a lock-in gasifier, which not only can

Withstand pressure, while having common features.

Features:

(1) The unloader adopts the principle of planetary rotation, the input and output are on the same axis, and it has the uniqueness of being directly integrated with the motor, so the structure is compact and beautiful.

New concept, small size, lightweight.

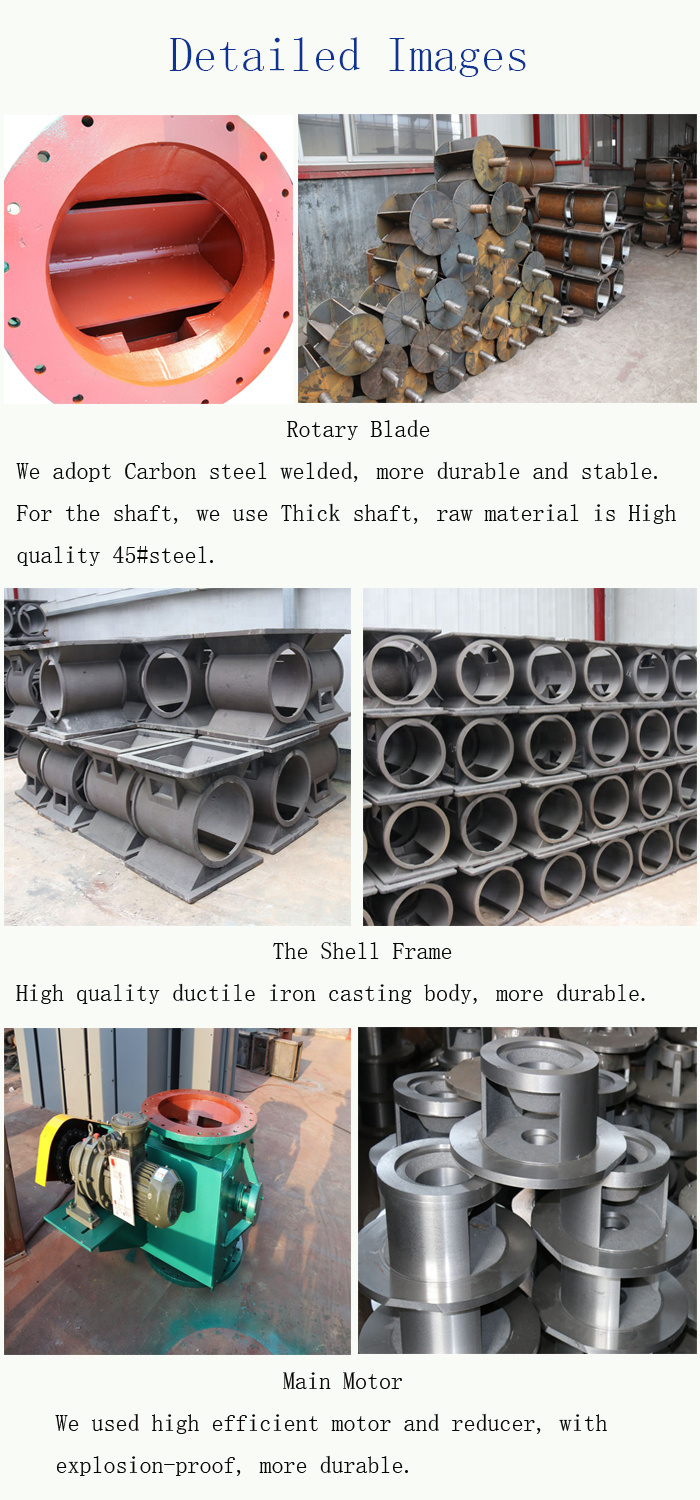

(2) unloader operation is reliable and stable, low noise, low failure, long life, toothed joints with ductile iron and bearing steel, etc.. Good performance, high wear resistance.

(3) bearing, gear box, away from the valve body, to avoid the impact of high temperature dust, the front and rear end caps have good sealing performance, prevent the leakage of dust, extend the motorized parts, lubrication system

Service life.

(4) The unloader has strong overload capacity, low impact moment of inertia, and is suitable for frequent start and reverse rotation.

(5) If users need special specifications, unloaders such as motors and sprocket drives can be made.

Applicable precautions:

1. Before using the star unloader, check the amount of oil in the reducer and the type of oil. After one month of operation, replace the new oil and change the oil once a year.

2. Connect the gas source interface, check whether the interface is blocked by foreign matter, and ensure that the interface is clean and smooth;

3.Before using the star unloader, be sure that the rotation direction of the rotor is clockwise (view from the reducer out of the shaft end, which is consistent with the arrow on the sprocket cover);

4. Before using the star unloader, open the sprocket cover to check the tension of the chain and check it regularly during the operation; apply the chain and sprocket together.

Suitable grease

5. During the whole use of the unloader, it is advisable to adjust the pressure reducing valve so that the pressure at the seal is greater than the material pressure in the valve body of 0.05 MPa. The gas is oil-free,

Dry compressed air;0.

6. During the entire use of the star unloader, the gas source at the seal is always present, and the gas source can be closed only after it is confirmed that the valve is out of service.

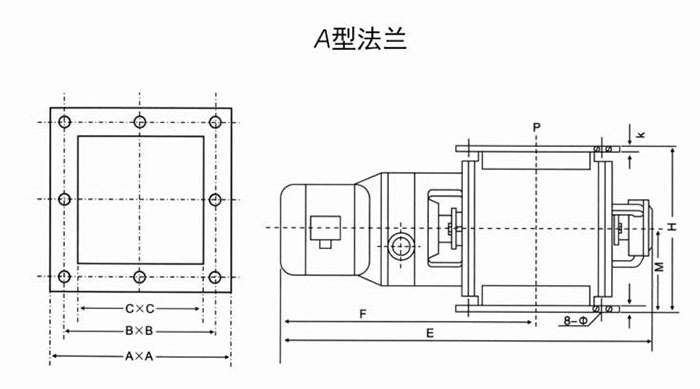

| Model | A | B | C | E | F | M | H | h | n-φ | It also can be customized. |

| YJD02 | 240 | 200 | 150 | 650 | 420 | 122.5 | 225 | 12 | 8-9 | |

| YJD04 | 260 | 230 | 180 | 758 | 526 | 140 | 280 | 15 | 8-11 | |

| YJD06 | 280 | 250 | 200 | 778 | 536 | 150 | 300 | 15 | 8-11 | |

| YJD08 | 300 | 270 | 220 | 798 | 546 | 160 | 320 | 18 | 8-11 | |

| YJD10 | 320 | 290 | 240 | 880 | 628 | 170 | 340 | 18 | 8-13 | |

| YJD12 | 340 | 310 | 260 | 900 | 638 | 180 | 360 | 18 | 8-13 | |

| YJD16 | 380 | 350 | 300 | 960 | 678 | 200 | 400 | 20 | 8-17 | |

| YJD26 | 480 | 450 | 400 | 1150 | 740 | 260 | 520 | 24 | 8-17 | |

| YJD30 | 600 | 520 | 440 | 1190 | 755 | 300 | 600 | 24 | 12-17 |

Keywords

Leave Us A Message

*Note: Please fill in the information accurately and keep the communication open. We will contact you as soon as possible.