PRODUCTS

CONTACT INFO

Email: sales01@everluckymachinery.com

Whatsapp: +86-13722852356

Wechat: ff0082006

Sype: 297338284@qq.com

Tel: +86-317-5660915

Fax: +86-317-8330026

Address: Botou city Hebei province

back pressure double flap check valve

Double-layer electric lock air flap valve, also known as lock air feeder, has two categories, single door and double door, which are generally applicable to building materials, metallurgy, chemical in

Category

Contact Info

sales01@everluckymachinery.com

Product Details

Double-layer electric lock air flap valve, also known as lock air feeder, has two categories, single door and double door, which are generally applicable to building materials, metallurgy, chemical industry, electric power and other industries. As the unloading device of various types of dust removal equipment, hopper discharge equipment and various grinding equipment, dryers, silos and other equipment to the unloading device to prevent wild wind blowing.

Working principle:

The transmission rod is driven by the speed reducer to drive the upper and the lower two transmission shafts to rotate through the crank, the cam and the connecting rod respectively, and is opened interactively. Through the equipped lever system or the extension spring, the valve plate can be reliably reset to prevent the wild wind from being blown into. The unloading of the system is completed according to the determined opening and closing frequency.

Feature:

The double-layer electric lock flap has two sealing surfaces. The two sealing surfaces of the most commonly used mode gate valves form a wedge, and the wedge angle varies with the valve parameters. Usually 50. The gate of the wedge plug valve can be made in one piece, called a rigid gate. It can also be made into a gate that can produce a slight amount of deformation, in order to improve its process ability, make up for the deviation of the sealing surface angle in the processing process. This gate is called a flexible gate. When the flapper valve is closed, only the medium pressure can seal the sealing surface, that is, the pressure of the medium presses the sealing surface of the gate plate to the valve seat on the other side to ensure the sealing of the sealing surface. This is self-sealing. Most of the plug-in valve is forced to seal, that is, when the valve is closed, it must rely on external force to force the gate to the valve seat to ensure the sealing surface of the seal.

| A | B | C | A1 | B1 | C1 | H | L | N-φ | Discharging capacity (M3/n) | Open frequency (t/m) | Temperature | Reducer model | Motor power | Weight |

| φ300 | φ260 | φ200 | 290 | 250 | 200 | 680 | 1540 | 8-φ13 | 12 | 17 | ≤350℃ | XWD3-59 | 0.55-6 | 124 |

| φ 320 | φ280 | φ220 | 310 | 270 | 220 | 680 | 1690 | 8-φ13 | 14 | 17 | ≤350℃ | XWD3-59 | 0.55-6 | 162 |

| φ340 | φ300 | φ240 | 330 | 290 | 240 | 680 | 1710 | 8-φ13 | 17 | 17 | ≤350℃ | XWD3-59 | 0.75-6 | 216 |

| φ360 | φ320 | φ260 | 350 | 310 | 260 | 860 | 1840 | 8-φ13 | 19 | 17 | ≤350℃ | XWD3-59 | 0.75-6 | 288 |

| φ380 | φ340 | φ280 | 380 | 330 | 280 | 860 | 2010 | 8-φ18 | 20 | 12 | ≤350℃ | XWD3-71 | 0.75-6 | 423 |

| φ400 | φ360 | φ300 | 400 | 350 | 300 | 860 | 2030 | 8-φ18 | 23 | 12 | ≤350℃ | XWD3-71 | 1.1-6 | 552 |

| φ420 | φ380 | φ 320 | 420 | 370 | 320 | 1000 | 2280 | 8-φ18 | 25 | 12 | ≤350℃ | XWD3-71 | 1.1-6 | 773 |

| φ440 | φ400 | φ340 | 440 | 390 | 340 | 1000 | 2310 | 8-φ18 | 28 | 12 | ≤350℃ | XWD3-71 | 1.1-6 | 1037 |

| φ500 | φ460 | φ400 | 510 | 510 | 400 | 1100 | 2370 | 8-φ18 | 35 | 12 | ≤350℃ | XWD4-71 | 1.5-6 | 1260 |

| φ610 | φ560 | φ480 | 600 | 550 | 480 | 1200 | 2470 | 16-φ18 | 50 | 12 | ≤350℃ | XWD4-71 | 1.5-6 | 1420 |

| φ 660 | φ610 | φ500 | 660 | 610 | 500 | 1200 | 2480 | 16-φ18 | 52 | 8 | ≤350℃ | XWED53-121 | 1.1-6 | 1638 |

| φ 670 | φ620 | φ540 | 670 | 620 | 540 | 1200 | 2620 | 16-φ18 | 55 | 8 | ≤350℃ | XWED53-121 | 1.1-6 | 1894 |

| φ740 | φ680 | φ 600 | 730 | 680 | 600 | 1200 | 2620 | 16-φ18 | 60 | 8 | ≤350℃ | XWED64-121 | 1.5-6 | 2458 |

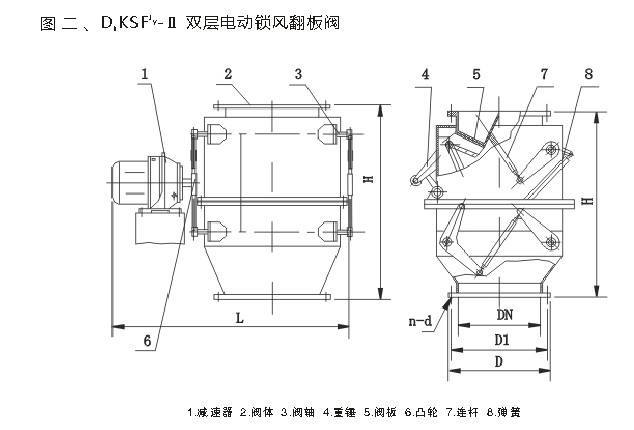

1.Reducer 2. Valve body 3. Valve shaft 4. Hammer 5.Valve plate 6.Cam 7.connecting rod 8. Crank

Keywords

Leave Us A Message

*Note: Please fill in the information accurately and keep the communication open. We will contact you as soon as possible.